Introduction

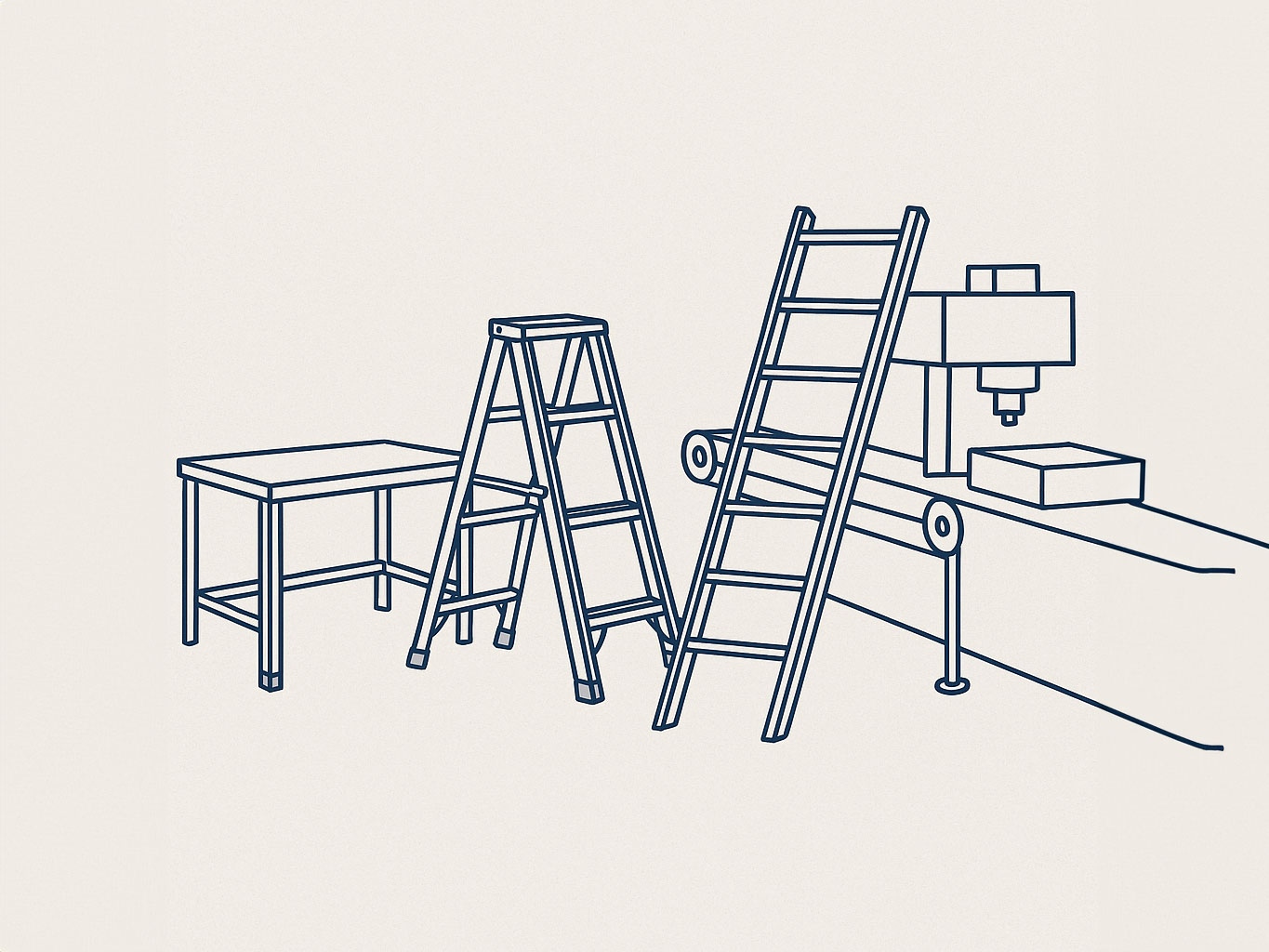

In manufacturing sites, high-altitude work such as assembly, inspection, and testing occurs on a daily basis. Especially in line work, it is important to select workbenches, stepladders, and ladders that combine safety and efficiency. However, issues such as “falling on unstable scaffolding” and “unnatural posture due to lack of appropriate size” are often seen on site.

There are many accidents related to working at height in Vietnam, and strengthening safety measures is required. In this article, we will introduce the current situation and risks of high-altitude work in the manufacturing industry, points to consider when selecting products that balance safety and work efficiency, and implementation examples with primary information.

Risks of working at height and safety issues in manufacturing sites

Market data

In Vietnam’s manufacturing industry, the use of workbenches, stepladders and ladders is commonplace in processes such as electronic equipment and parts assembly, painting and inspection. According to the Ministry of Labor, Invalids and Social Affairs of Vietnam (MOLISA) in 2023, approximately 30% of industrial accidents were caused by working at height, many of which were due to unprepared scaffolding and inappropriate lifting equipment.

In addition, with the spread of ISO 45001, fall prevention measures are becoming mandatory for work at heights of 2m or more, but some say that measures are difficult to implement in work sites where workers move frequently, such as line work.

Source _ English Version: Vietnam MOLISA 2023 Annual OSH Report

Risk presentation

The main risks of working at height are as follows:

- Tipping and falling accidents: The main causes are unstable installation of stepladders and unused opening stoppers.

- Accidents due to improper use: Misbehavior such as standing on the top board or leaning out.

- Fatigue accumulation and poor posture: Unnatural postures become the norm due to lack of a work platform of appropriate height and width.

In fact, a survey by Hasegawa Kogyo reported that **more than half of accidents related to work at height are caused by “incorrect use” and “miss election of equipment.”

Source: [Safe use of products (Hasegawa)]

https://www.hasegawa-kogyo.co.jp/support/howto/kyatatsu.php

Repeated work at height in manufacturing sites is exactly what requires a review of appropriate equipment and usage.

How to choose and benefit from stepladders, ladders and work platforms for manufacturing

Features

In manufacturing lines, equipment must be selected within the triple constraints of “limited space,” “continuous work,” and “compliance with safety standards.” Hasegawa’s work platforms, stepladders and ladders solve on-site problems with the following features.

- Lightweight and durable aluminum construction: Less tiring to carry for long periods of time, and resistant to corrosion

- Models with height adjustment and folding function: Can be optimized according to the worker’s height and the work site

- Safety lock mechanism and opening stopper included: Greatly reduces the risk of accidental falls

For example, Hasegawa’s DSL series scaffolding platform has a adjustable top height between 0.63 and 1.20 m. It ensures a stable standing position even when working across steps on assembly and packaging lines.

In addition, the RAX series stepladders are made of aluminum alloy with leg covers and have a maximum load capacity of 130 kg, making them very sturdy and ensuring stability even when working while standing and working upwards.

Case studies (Before → Action → After)

■ Case 1: Electronic parts assembly line (Company A)

- Before: The traditional fixed work platforms were not the right height, which caused strain on the shoulders and back of workers. Work speeds also varied from day to day.

- Action: The height-adjustable DSL1.0 scaffolding platform (top height 0.89 to 1.20 m) was introduced, optimizing the height for each worker.

- After: The workers’ posture improved, and work time per line was reduced by an average of 12%. Turnover rate also showed a slight improvement.

■ Case 2: Logistics area in a factory (Company B)

- Before: When stacking packaged products, it was common for workers to work on cardboard boxes.

- Action: The lightweight and easy-to-carry DRSW series (tabletop height 65-123 cm) was introduced.

- After: By ensuring stable footing, we achieved zero falls. We were also able to reduce the number of items to be recorded in the safety management report.

In this way, the introduction of appropriate stepladders, ladders, and workbenches contributes to both accident prevention and productivity improvement, not only from the perspective of work efficiency but also safety management.

Criteria for choosing a reliable workbench

Quality control and certification

When selecting a product with safety as the top priority, third-party certification and the presence or absence of a quality assurance system are important criteria for judgment. Many of Hasegawa Vietnam’s stepladders and workbenches have acquired ISO9001 (quality management system), and consistent quality control is carried out from the manufacturing process to after-sales support after shipment.

In particular, the following inspection system has been highly evaluated by manufacturing sites both in Japan and overseas.

- Static load test and vibration resistance test to verify product strength

- Selection of materials with corrosion resistance and wear resistance

- Multilingual support for labels and safety indications (including Vietnamese)

In addition, demonstration tests in outdoor storage and oil environments are also conducted to ensure that the products can withstand the harsh conditions of the workplace, making the difference in reliability “a difference that cannot be measured by appearance or price.”

Customization and support system

In the manufacturing industry, there are many site-specific requirements, such as “We need a size that does not interfere with equipment” and “We want the height to be set according to the height of the worker.” Hasegawa’s customization service meets these needs.

- Specify tabletop height and width in 1cm increments

- Anti-slip processing and caster specifications

- Process-specific management by specifying the color of stepladders and work tables

In addition, the following support system is in place to support continued safe operation even after introduction.

- Operation explanation video and safe use PDF manual (free)

- Regular inspection service and on-site safety training (consultation required)

- Parts supply and repair support in case of damage

Especially for companies with bases in Vietnam, the peace of mind of being able to use Japanese quality products locally is a major deciding factor when introducing them.

As mentioned above, it is essential to choose products that are not just “tools” but also have the reliability appropriate for manufacturing sites as equipment that protects the lives and productivity of workers.

Summary: How to balance safety and efficiency in working at height

In manufacturing sites, work at height, which requires both “efficiency” and “safety,” occurs on a daily basis. There, appropriate product selection and thorough worker education are of utmost importance.

In this article, we have explained the selection criteria for work platforms, stepladders, and ladders, and the effects after introduction, while taking into account the accident data and legal background of work at height in Vietnam. In particular, Hasegawa’s stepladders, work platforms, and ladders are increasingly being adopted on site for the following reasons.

- Reliability through ISO certification and rigorous quality testing

- Flexible product specifications such as height adjustment and customization

- Achieving both work efficiency and safety as seen in concrete implementation cases

For those in charge who want to “create a safe working environment” or “introduce the optimal work platform or ladder for their own line.” Hasegawa provides support in Japanese and Vietnamese from product introduction consultation to specification selection and document provision.