Introduction

To everyone responsible for selecting industrial ladders and stepladders for factories, construction sites, and warehouses in Vietnam: Are you struggling with questions like “What’s the best product for our site?”, “Is it safe?”, or “What about the cost?”

Choosing the right industrial ladder or stepladder is a critical task directly linked to ensuring employee safety, work efficiency, and cost management. An inappropriate product can lead to serious accidents and decreased productivity.

This article provides a clear, expert explanation of the essential “7 Checkpoints” to avoid such failures and find the perfect equipment for your site. We will cover specific points, from safety standards to selecting the right application and material, load capacity, height, and choosing a reliable manufacturer. Please read on and use this guide to help create a safe and efficient work environment.

Why is the Way You Choose Industrial Ladders & Stepladders Important?

Industrial ladders and stepladders are convenient tools, but their selection and use require careful attention. Let’s delve into why choosing the right product is so crucial.

The Risk of Falls and the Need for Safety Assurance

Unfortunately, occupational accidents involving falls from ladders and stepladders continue to occur. According to statistics from the Ministry of Health, Labour and Welfare (Japan), “falls” are the most common cause of fatal accidents, and a significant number of these involve ladders and stepladders. Ensuring safety during high-altitude work is also an urgent issue here in Vietnam.

An accident can lead to immeasurable damage, not only for the injured employee but also for the company, including human and economic losses, production stoppages, and damage to social credibility. To protect employees’ safety and ensure business continuity, selecting the right product to reduce risks is essential.

Costs and Inefficiencies Caused by Inappropriate Product Selection

It’s not uncommon for products chosen solely based on being “the cheapest” to turn out unsuitable for the actual work content or environment. For example:

- Products with low durability: Break or deteriorate quickly, requiring frequent replacements.

- Products unsuitable for the task: Make work difficult and time-consuming, reducing productivity.

- Products that are too heavy or difficult to handle: Take time and effort to carry and set up, worsening work efficiency.

This situation is truly a case of “penny-wise and pound-foolish.” What seemed like saving on initial costs can end up being more expensive in the long run due to repair costs, replacement expenses, and indirect losses from reduced work efficiency.

Choosing the right industrial ladder or stepladder is not only an investment in safety but also a wise management decision that leads to long-term cost reduction and improved productivity.

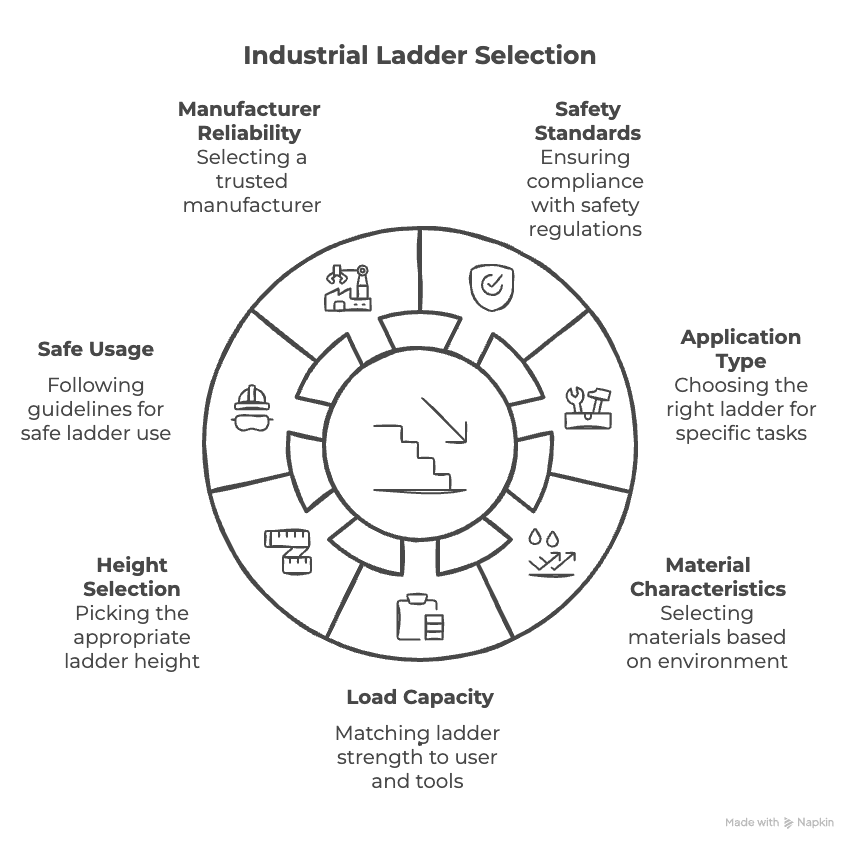

Avoid Failure! 7 Checkpoints for Choosing Industrial Ladders & Stepladders

Let’s take a detailed look at the specific “7 Checkpoints” to avoid failure when selecting industrial ladders and stepladders. Following these points will help you choose a safer product that better meets the needs of your site.

Point 1: Check for Safety Standards and Compliance

The most crucial first step is to verify that the product complies with established safety standards and regulations. Compliant products are proof that their structure, strength, and materials meet certain safety levels, reducing the risk of accidents.

- Why choose compliant products?

- To prevent accidents caused by design flaws or insufficient strength.

- From a legal compliance perspective (especially for use within Vietnam).

- As an indicator of quality reliability.

- Major Safety Standards:

- JIS (Japanese Industrial Standards): High safety standards from Japan. For example, standards like 100kg (equivalent to JIS1000 type) or 130kg (equivalent to JIS1300 type) exist based on the maximum usable mass (explained later). Many Hasegawa products comply with these strict JIS standards, boasting high safety.

- TCVN (Vietnam National Standards): Standards that must be complied with for use within Vietnam. Checking compliance with these standards is crucial for procurement and use domestically.

- EN131 (European Standard): An international safety standard widely adopted, primarily in Europe.

- ISO (International Organization for Standardization): While not a product standard itself, certifications like ISO 9001 (Quality Management System) indicate the reliability of a manufacturer’s quality control system.

- How to Check: Look for standard marks (like the JIS mark) or compliance statements on the product itself, in catalogs, or specification sheets. If unsure, it’s important to inquire with the manufacturer or retailer.

Point 2: ‘Where’ and ‘What For’? Choose the Right Type for the Application

There are various types of ladders and stepladders, each suited for different purposes. Choose the optimal type based on the work content and location.

- Recommended Types by Application:

- Construction Sites: Often involve work at heights, requiring robustness and stability. Relatively tall “Double/Triple Extension Ladders,” “Work Platforms (Scaffolding Platforms)” that provide a stable footing, or “Heavy-Duty Stepladders” are suitable.

- Electrical Work: To avoid the risk of electric shock, ladders and stepladders made of “FRP (Fiber Reinforced Plastic),” which offers excellent insulation, are essential.

- Warehouses & Factories: Various tasks at different heights occur, such as picking goods and equipment maintenance. “Combination Ladders” that can adapt to multiple heights, “Work Platforms” with wide, stable top plates, or specialized “Picking Steps” for accessing specific shelves are convenient.

- Retail Stores & Light Work: Primarily involves work at relatively low heights, like stocking shelves, changing displays, and cleaning. Easy-to-carry “Lightweight Aluminum Stepladders” or products with good design are suitable.

- Other Special Applications: There are products meeting specialized needs, such as “Tripod Ladders” for orchard maintenance in agriculture, products with outriggers for installation on unstable ground, and “Custom-Made Products” for accessing specific equipment.

Hasegawa Vietnam offers a wide range of products to meet these diverse applications. If standard products don’t suffice, custom manufacturing is also possible, so please feel free to consult us.

Point 3: ‘In What Environment’? Know the Material Characteristics

The product’s material significantly affects its durability, weight, price, and safety (especially for electrical work). Choose the optimal material based on the usage environment.

- Aluminum:

- Pros: Lightweight and easy to carry, resistant to rust and relatively easy to maintain, wide price range.

- Cons: Conducts electricity, so avoid use near electrical equipment; can deform under strong impact.

- Suitable Environments: General indoor and outdoor work (construction, equipment maintenance, warehouses, stores, etc.).

- FRP (Fiber Reinforced Plastic):

- Pros: Extremely high insulation properties, stronger and less prone to deformation than aluminum, excellent corrosion and chemical resistance.

- Cons: Heavier than aluminum and tends to be more expensive.

- Suitable Environments: Electrical work, chemical plants, coastal areas, and other locations requiring insulation or corrosion resistance.

- Stainless Steel:

- Pros: Most resistant to rust and corrosion, hygienic.

- Cons: Heavy and very expensive.

- Suitable Environments: Food factories, pharmaceutical plants, clean rooms, marine-related applications, and other special environments requiring extremely high corrosion resistance or hygiene management.

It’s crucial to consider the usage environment—whether it’s indoors or outdoors, humid, near electrical equipment, or involves chemicals—to select the most suitable material.

Point 4: ‘Who’ and ‘What’ Will Be On It? Always Check the “Maximum Usable Mass (Load Capacity)”

“Maximum Usable Mass” refers to the maximum weight that the ladder or stepladder can support. This is the total weight, including the user’s body weight plus the weight of tools, materials, and worn equipment.

- Why is it important? Exceeding the maximum usable mass can cause the product to break or deform, leading to a very high risk of serious falls.

- Guideline for Industrial Use: For general industrial use, it is recommended to choose products with a maximum usable mass of at least 100kg, preferably 130kg or more (referencing JIS standards, etc.). Especially for frequent use or when working with heavy tools/materials, select a product with a more generous load capacity.

- How to Check: It is always listed on labels affixed to the product, in the instruction manual, or in the catalog specifications. Always check before purchase and ensure that the actual usage conditions (worker’s weight + anticipated load weight) are within the permissible range.

Point 5: ‘At What Height’ Will You Work? Choose the Appropriate Height

To safely reach the target work area, you need to select a product of the appropriate height.

- “Working Height” vs. “Product Height”: The “overall length” or “top plate height” listed in product specifications is not the height at which you can safely work. Generally, standing on the top step of a stepladder is prohibited, and for ladders, it’s considered safe to place your feet no higher than the third (or fourth) rung from the top.

- Height Selection Guideline:

- For Stepladders: A product with a top plate height roughly equal to the target work height minus your own height and reach is a good estimate.

- For Ladders: Considering the setup angle (usually around 75 degrees), choosing a ladder with an overall length about 1 meter longer than the work point makes safe ascent/descent and work easier.

- Risks of Too High / Too Low:

- Too High: Can be difficult to transport and set up, or cumbersome in tight spaces.

- Too Low: Can induce dangerous behaviors like working in awkward postures or stepping onto the top plate.

- Convenient Features: If the working height varies, “Telescopic Types” or “Combination Ladders” that can adapt to multiple heights are very convenient.

Consider the work content and location, and carefully choose a height that allows for safe and effortless work.

Point 6: ‘How’ Will You Use It? Confirm Safe Usage Methods and Installation Location

No matter how excellent the product chosen, incorrect usage can lead to accidents. Simultaneously with product selection, thoroughly enforcing safe usage methods is extremely important.

- Check the Installation Location:

- Always install on a level, stable, and firm surface. Avoid uneven ground, soft surfaces, or slippery floors.

- Ensure there is sufficient space at the installation site.

- Check Structural Safety Features:

- Stepladders: Before use, always confirm that the “spreader bars” (locking mechanism) are securely locked.

- Ladders & Stepladders: Check that the “non-slip caps (feet)” on the legs are not worn out or detached.

- Correct Usage:

- Stepladders: Do not stand or sit on the top plate to work. Work within the range of the steps (rungs).

- Ladders: The basic angle for leaning against a wall is approximately 75 degrees. When ascending or descending, always face the ladder and hold the stiles with both hands (3-point contact).

- Avoid carrying tools in your hands while climbing. Use tool bags or ropes if necessary.

- Do not lean out too far. Work within a range where you won’t lose balance.

- Regular Inspections: Make pre-use checks a habit and periodically inspect for deformation, damage, loose parts, etc. If any abnormalities are found, absolutely do not use the product; repair or replace it.

Information regarding these safe usage methods is also included in the product’s instruction manual. Be sure to review it beforehand and ensure it is shared and adhered to by all workers.

Point 7: Choose a Reliable Manufacturer and Product

The final point is to choose products from a reliable manufacturer. The manufacturer’s reliability directly impacts product quality, safety, and after-sales support.

- Why is Manufacturer Selection Important?

- Quality and Safety: Established manufacturers produce items under strict quality control systems based on years of experience and technology. This reduces the risk of design and manufacturing defects.

- Standard Compliance: Reliable manufacturers often offer products that comply with official safety standards like JIS.

- Durability: High-quality materials and robust design ensure products last longer, resulting in better cost-effectiveness.

- Support System: You can expect appropriate support, from pre-purchase consultation to post-purchase maintenance and parts supply.

- Points to Identify a Reliable Manufacturer:

- Track Record and History: Have they been operating in the industry for many years?

- Technological Capability: Do they possess product development capabilities or unique technologies?

- Quality Control System: Are their quality management efforts clear (e.g., ISO certification)?

- Product Lineup: Do they offer a wide range of products to meet diverse needs?

- Customer Support: Is their response to inquiries and warranty coverage solid?

- Risks of Cheap Non-Branded Products: Choosing based solely on low price can lead to problems with safety and durability. There’s a possibility that adequate quality control was not performed or that safety standards were not met.

Hasegawa Kogyo Co., Ltd. is a leading Japanese company with over 60 years of history, and its Vietnamese base, Hasegawa Vietnam, inherits Japan’s high technological capabilities and strict quality standards. Under the philosophy “Safety is the top priority,” we continue to provide high-quality, reliable products that comply with various safety standards, including JIS. Manufacturer reliability is an extremely important criterion when choosing industrial ladders and stepladders.

Your Partner for Problem Solving: The Strengths of Hasegawa Vietnam

Choosing the optimal industrial ladder or stepladder is the first step towards ensuring safety and efficiency. However, finding the best fit from numerous products and using it reliably long-term requires a trustworthy partner.

As the Vietnamese base of Japan’s leading company, Hasegawa Kogyo Co., Ltd., we at Hasegawa Vietnam strongly support our customers in solving their challenges. Here, we introduce the unique strengths of Hasegawa Vietnam.

Unwavering Commitment to Japanese-Standard Quality and Safety

At the core of the Hasegawa Group’s manufacturing lies the unchanging philosophy since its founding: “Safety takes precedence over everything.” This principle permeates all products and services of Hasegawa Vietnam.

- Japanese Technology and Strict Standards: We employ advanced design technology cultivated by Hasegawa Kogyo over 60 years, along with product development and manufacturing processes based on Japan’s stringent quality control standards, including JIS.

- Thorough Quality Assurance: Products are delivered after rigorous quality inspections conducted in factories certified under the international quality management system standard ISO 9001. This ensures consistently high quality.

- Long-Term Cost Benefits: We focus on details not apparent at first glance, providing highly durable and safe products. This reduces costs associated with frequent replacements and the risk of accidents, contributing to improved long-term cost efficiency for our customers.

The reliable quality and safety backed by “Made in Japan” expertise is one of the greatest values Hasegawa Vietnam offers its customers.

Wide Product Lineup and Customization Capabilities to Meet Diverse Needs

The requirements for industrial ladders and stepladders vary greatly depending on the site. Hasegawa Vietnam is structured to respond to all customer situations.

- Extensive Standard Products: Our lineup includes a wide variety of standard items, from general aluminum ladders and stepladders to FRP products with excellent insulation, highly stable work platforms, and agricultural tripods. We can meet basic customer needs from various applications and sizes.

- The “Custom-Made (Order-Made)” Option: “I need a work platform with dimensions that perfectly fit the installation space,” “We need a dedicated step for maintaining specific machinery,” “Can you make it with a special material?” – Hasegawa Vietnam responds to these site-specific challenges, which standard products cannot solve, with custom manufacturing. We carefully listen to customer requirements, handle everything from design to manufacturing, and create the world’s only optimal product.

- Track Record of Problem Solving: We have contributed to solving problems for customers in various industries within Vietnam (manufacturing, construction, food processing, etc.) through custom-made products. (We would be happy to share specific case studies separately.)

We respond to customer requests like “If only there were such a product…” with our technology and experience.

Reliable Support System within Vietnam

From before product introduction to after, Hasegawa Vietnam stays close to its customers, providing meticulous support.

- Expert Product Selection Support: Our knowledgeable staff will inquire about your work details, usage environment, budget, etc., and assist you in selecting the optimal product. We provide accurate advice via phone, email, and, if necessary, site visits.

- Comprehensive After-Sales Service: We responsibly handle post-purchase inquiries about products, guidance on correct usage and maintenance methods, and consultations for repairs in case of unlikely issues.

- Prompt Domestic Supply: Hasegawa Vietnam is a local subsidiary based in Vietnam. Through domestic inventory management and supply systems, we strive to deliver products as quickly as possible when customers need them. Please feel free to consult us regarding delivery times.

In addition to product quality, a support system that provides total peace of mind from introduction to operation is also a strength of Hasegawa Vietnam.

Summary

When choosing industrial ladders and stepladders, it is important to check the following seven points:

- Safety Standards & Compliance

- Application (Usage)

- Material

- Maximum Usable Mass (Load Capacity)

- Height

- Safe Use & Installation

- Reliable Manufacturer

“Safety is an investment that cannot be compromised.” Based on these points, selecting the optimal product tailored to the site conditions protects worker safety, enhances work efficiency, and leads to long-term cost reduction.

Hasegawa Vietnam offers high-quality products that meet diverse customer needs and a reliable support system. For product details, catalog requests, custom product consultations, or any other questions, please feel free to contact us via the inquiry form or by phone.

We hope this article serves as a helpful guide in your selection of the perfect equipment.